The tensile property of the yarn can be defined as the maximum force required to break or disintegrate the material. This parameter is very important in the production of yarn, because it directly affects the strength of the fabric made with yarn. Two methods are used to measure yarn strength. In the first method, the strength of monolayer is determined. Newton (N) and cN units are usually used to determine yarn strength. The amount of force required for an object with a mass of one kilogram to start moving at a rate of one meter per square second is called a Newton force. One-layer yarn strength provides information about yarn spinning machine and knitting machine efficiency. In order to calculate the effect of yarn compound strength, the yarn strength strength product (CLSP) of yarn is calculated. A 120-yard Lee is produced using a yarn wrapping tube. Lee’s weight is determined by calculating the yarn score with the following formula: The number of yarn spuns divided by their weight in pounds. Li strength is determined using a Li strength device that has two jaws (one of which is fixed and the other is connected to the load). Using the principle of constant loading rate, the tensile strength of Lee can be determined.

Constant tensile rate (CRE)

Such machines have a constant elongation rate of the laboratory sample; As the load increases, the measuring mechanism will have very little motion. This device is based on the Tensorapid-4 principle, which is used to measure the tensile strength of a single-strand yarn that has a constant elongation rate.

Constant loading rate (CRL)

In this case, the device enters the load on the sample, which over time increases the amount of load continuously. The test specimen can be drawn freely, the degree of tension of the yarn depends on the characteristics of the load applied to it. Lee’s strength device works on this principle.

Fixed Traverse Rate (CRT)

In this type of device, two tensile clamps are used to evaluate the tensile strength of the sample. One clamp moves at a constant speed and the load is applied by the second clamp; This clamp is responsible for activating the load measuring mechanism. Older devices, such as fabric tensile strength testers, typically use this mechanism.

Determination of tensile strength of yarn

Tensile strength of yarn by coiled method

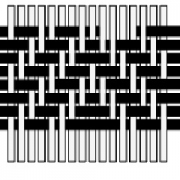

In this method, the thread is wrapped by a tube on a coil known as Lee; This method is used to measure the linear density of the yarn, in which the two free ends of the yarn are tied together. Lee mounts on two jaws of the tensile strength tester. Lee is then subjected to an incremental tensile force and the force exerted on it is recorded. Since a part of Lee finally breaks at a point in the weakest area of the yarn, the maximum force applied refers to the pound or kilogram. The minimum strength of 10 li should be measured from the same score using the above method and then the average of the measurements should be calculated. The English standard refers to 10 li or coil wrapped at a distance of 1 meter 100 turns. This test is performed at a certain speed, in other words, the breaking point is between s 3 ± ۲۰ On the other hand, a constant speed of 300 mm per minute may also be used. Most likely, the yarn that should be spun on a 10-spool wool or cotton frame should be tested with at least 20 wool spins. This method does not apply to yarns made of durable fibers.

Product strength score or CLSP

Product Quality Assessment (CLSP) is a term used to assess the quality of staple and spun cotton yarns. This factor depends on the quality of the Lee formed on the rotating tube with a circumference of 1.5 yards; Lee’s 80 spins have a length of 120 yards. In this case, quality is usually expressed in pounds-force (lbf). The yarn strength is also measured in pounds, then multiplied by the English cotton yarn score to finally obtain the product strength score or CLSP.

CLSP (product strength Lee score) = score (Nec) * Lee strength (in pounds)

Tensile strength by monolayer method

Yarn tensile testing is usually performed according to ISO 2062 and ASTM D2256 standards. These tests are performed to determine the force required for yarn rupture, elongation, and to determine the yarn stiffness characteristics (force required for yarn rupture). Yarn break strength is the ratio of the force required to break a yarn to its linear density, and is a common feature for evaluating the strength of yarn components and a tool for testing and validating experiments. Tying the test sample thread is necessary because the loading axis must be aligned with the sample axis. This alignment can be easily achieved and repeated using belt pin clamps. Factors such as sharp edges or changes in the test path may cause the sample to fail outside the measuring section, in which case the strength obtained will be much less than the actual strength of the yarn. Belt clamps also help prevent this, as the yarn will never undergo severe geometric changes if used. Since the elongation properties are very important in the application of cotton products, the yarn should be prevented from slipping during the test; Therefore, instead of using a set of clamp jaws, the load is evenly distributed on the straps.

Leave a Reply

Want to join the discussion?Feel free to contribute!