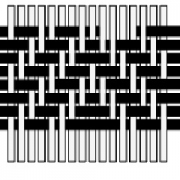

Stenter machine has a very important role in dyeing, printing and finishing operations on fabrics, the most important of which is to create dimensional stability on the fabric. The method of this machine is that the fabric is inserted into the machine in an open width and the edges of the fabric are restrained and stretched on both sides in the form of needles or clips. The amount of elongation in this machine depends on the final width of the fabric. Dimensional stabilization is done by heat.

Introduction

Most industrialized and developed countries first started with the textile industry and built a bridge from this industry to reach stable economic frontiers and other industries, including the United Kingdom, Italy, Germany and France, which today are industrialized and developed countries. They are remembered. Although our country has been the flagship of this industry in the distant past, according to the museums of the world, but unfortunately today we could not benefit much from this industry. At present, our textile industry has been hit hard by the entry of Chinese products into the market. On the other hand, in our country in the field of textile industry, proper and necessary research has not been done. One of the factors of economic progress in this industry is research and innovation, which unfortunately has received less attention.

STENTER device

When the fabric is woven on a weaving machine in the warp and weft system, it is subjected to high tension, both in the warp and weft direction. So that if we cut a part of the woven fabric on the machine and put it on a flat surface to relax, after a while, due to the weaving stresses being removed from it, changes in the dimensions of the fabric will be achieved. . In other words, the fabric shrinks. How about we wash this cloth? In this case, in popular parlance, it is said that the cloth is gone. If, for example, this fabric is used to make a shirt or pants, after the first wash, the shirt or pants can no longer be used due to reduced dimensions. To overcome this problem, European craftsmen introduced a machine as a stenter, the basis of which is to create dimensional stability in the fabric. In this way, the fabric is inserted into this machine and the fabric is pulled to the desired width, then it is passed through a heat chamber. The fabric is thermostated and fixed after passing through this chamber.

The role of the stenter device

The role of the stenter machine in completing the textile product, both economically which is effective on the cost price of the product, and in terms of quality properties such as dimensional stability, subdivision, as well as various other complementary methods that are performed simultaneously in this machine. Due to the importance of this research device, its effect on the physical properties of warp and weft fabric, including resistance in the direction of warp or weft, is investigated. The method was defined as determining the blur and weft density of the fabrics before entering the stenter and also measuring these fabrics in the direction of the warp and weft. After leaving the stenter, the above tests were performed on the fabrics again. In fact, the purpose of this work is mainly to investigate the effect of the stenter on the two parameters of warp and weft density and resistance in the weft and weft direction.

Leave a Reply

Want to join the discussion?Feel free to contribute!