Visual inspection and grading of fabrics

This is the most common way to decide whether or not to accept a piece; In this method, the fabric roll is first loaded and the inspection table is equipped with different types of lamps with different lights and intensities. The fabric passes over the inspection table at a certain speed and a specialist visually examines the predetermined errors.

Based on the dimension, severity and nature of the fabric defects, a certain number of points are inspected per meter of fabric. Often the degree of freedom of the system being tested is more than one.

This is repeated for the entire sample rolls (selected from the total number of fabric rolls). At the end, the total points and area of the fabric to be tested are calculated. The results are then expressed in points per 100 square units (square yards or square meters) or 100 linear units (meters or yards) of fabric.

Fabric color test

A standard method for testing fabric color is to check the Pantone color reference number based on the color chosen by the customer. In this method, the dyed fabric is matched with the Pantone color reference and the fabric is accepted according to their degree of compatibility. Garment manufacturers usually match the color of the fabric with the color of the fabric sample already approved by the customer. Fabric samples are prepared in the pre-production stages according to the Pantone number specified by the customer. After the color samples have been approved after several tests, the supplier is asked to act on the approved items. The supplier is expected to use the same instructions in dyeing fabric samples.

Fabric tear resistance test

One thing that is generally considered about the parameters related to the strength of the fabric is the resistance of the fabric to tearing. This experiment has a special place in the fabric trade. The ball burst test is used to test the tear strength of the fabric. A sample of fabric taken from a fabric or garment roll is placed between the grooved plates of the test machine and fastened with screws. A rigid steel ball is attached to the actuator clamp of the machine pendulum which applies force to the fabric; The force is then applied to the fabric by the pendulum bullet from the right until the fabric is torn. The force required to tear the fabric (read from the machine) is the same as the tear strength of the fabric.

There are two standard methods for this test: the ASTM-D3787 reference is used at the traverse constant rate and the ASTM-D6797 reference standard is used at the fixed traction rate (CRE).

Yarn slip test

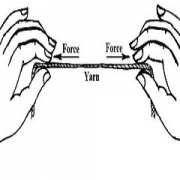

One of the major problems that occurs when sewing fabrics is the slipping of the yarn. Fabrics and other sewing products must be sufficiently resistant to slipping of the yarn along the seams. This test is performed to determine the resistance of the warp yarn to slip on the warp yarn or to test the resistance of the warp yarn to slip on the warp yarn using a standard seam.

To test the slip of the warp yarn on the weft yarn, a sample of the fabric is cut from its wider side along the weft of the fabric. The sample is then folded and a standard seam is made parallel to the warp yarn at a certain distance from the folded edge of the sample. In the next step, the sample is closed as a standard between the two jaws of the traction test machine; In this case, the fabric seam should be located in the center of the jaws. The fabric load elongation curve is placed on the fabric load elongation curve of the same type (which has a standard sewn seam parallel to the yarns being tested). Fabric resistance to yarn slip is expressed as a load in which slip of a certain size is observed. This test must be performed in accordance with ASTM-D434.

Air permeability

Permeability is the ability of a fabric to pass air perpendicular to its surface. This is an important test for accepting or rejecting commercial shipments. This is also very important in the production of clothing, because a fabric that has low air permeability does not allow sweat to evaporate; Hence, it causes skin irritation and bad body odor (due to the accumulation of sweat). Therefore, air permeability should probably be tested before selecting a fabric for clothing production.

In this experiment, by measuring the velocity of the air flow that passes vertically through the surface of the fabric, the difference in air pressure between the two surfaces of the fabric can be obtained. The amount of air permeability from the fabric surface is calculated based on the speed of air flow. The air permeability scale is cm3 / s / cm2 or ft3 / min / ft2. This test is performed according to ASTM-D737 standard.

Changes in fabric dimensions after washing

The amount of dehydration of the fabric is one of the most important factors in choosing a fabric for the production of clothing. If the fabric is not drained, the clothes may shrink after washing and the person may no longer be able to wear them. For this purpose, the amount of water loss of the fabric is calculated both in the direction of the warp and in the direction of the fabric weave, and the characteristics of the fabric in the cutting room are adjusted based on them. The sewn clothes may look big in terms of dimensions, but after washing, they match the sizes desired by the customers. This is exactly why the amount of elongation (stretch) of the fabric is very important.

To calculate the water flow rate of the fabric, a square sample is cut in a certain size from the fabric roll. Another square with dimensions smaller than this square is drawn inside it, the distance between the sides of the smaller square and the larger square should be the same in all 4 sides of the square. This is done because the edges of the fabric may shave during washing, reducing the size of the fabric; In this case, the actual water content of the fabric is not well known. The specified sample is then washed and dried according to standard conditions.

Leave a Reply

Want to join the discussion?Feel free to contribute!